It is a long established fact that a reader of a page when looking at its layout.

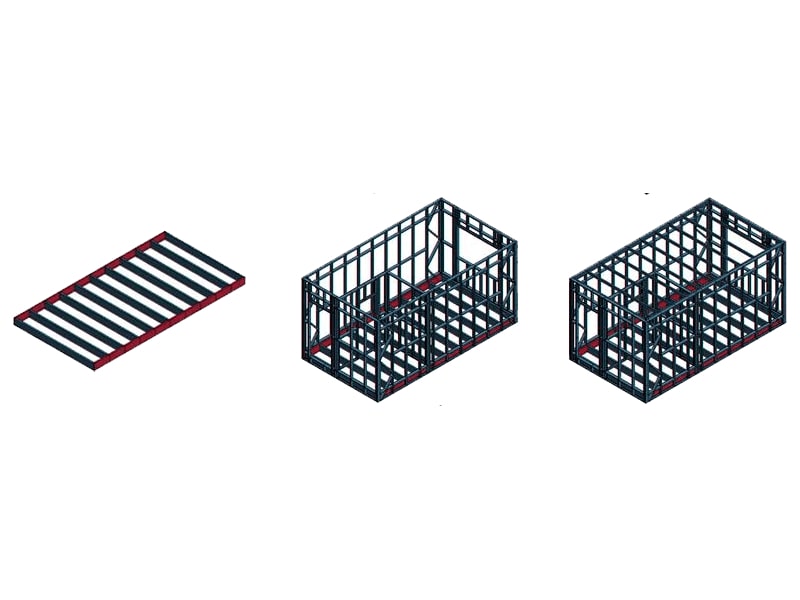

Volumetric Pods

Successful volumetric units require two different sections. The walls and ceiling can be produced using Bahal Buildcon framing machines. There are several buildings built up to 11 floors using the FRAMA 5600 machines due to Bahal Buildcon’s end-bearing detail. The cassette floors can be produced using the FRAMA 6800 floor joist machine.

Once the building design has been completed and the individual modules specified, the framing components can be made on a just in time basis for site delivery.

A typical assembly process would consist of:

Bathroom Pods

Bathroom pods are commonly used in the construction of most hotels and apartment buildings these days and becoming used more for residential housing.

The main drivers for choosing a modular pod method are:

These are less common, but are also becoming more frequently used. All the appliances and electrics are able to be fitted in the factory removing the need for work on site. Kitchen pods are ideal for renovating older or industrial buildings as all the electrical services for the building can be integrated into the pod.